OUR EMISSIONS TARGETS

AND NET ZERO PLAN

Recognising the urgent need to address climate change and reduce greenhouse gas emissions,

we have developed ambitious net zero targets and a high-level decarbonisation pathway to manage our value chain emissions

going forward. This aligns with our strategy of using ESG to drive our competitive advantage.

Targets

We have set science-based targets across Scopes 1, 2 and 3, which affirm our long-term commitment to net zero by 2040, and we have introduced interim targets for 2028. Our targets were validated by the Science Based Targets initiative (SBTi) in January 2024 and they provide a path for significant reduction in our emissions by 2028 and beyond.

By 2028, we have set the following targets:

- Reduce absolute Scopes 1 and 2 GHG emissions by 33.6% (2023 base year)

- Reduce absolute Scope 3 GHG emissions by 20.0% (2023 base year)

By 2040, our target is to reach net zero GHG emissions across the value chain.

Business model implications

As the UK and Ireland’s number one bathroom products group and a leading supplier of bathroom and kitchen products in our geographical markets, our business model already integrates certain emissions-reduction activities and products with sustainable attributes, and we will be increasing our focus on these areas to align our business and our products with a net zero world.

In developing our near-term decarbonisation plan for Scope 1 and 2, we assumed no material changes in our business model, locations or asset footprint or value chain impacts. Our belief is that we can make the necessary emissions reduction to our operations within a business-as-usual environment, utilising typical replacement cycles or initiatives that do not incur material capital expenditure or operational disruption. Beyond our near-term target date of 2028, we are reliant on the development of new technologies to reduce operational emissions to zero, in particular in the production of ceramic tiles (where we manufacture tiles in South Africa). In order to meet our emissions reduction targets, we will need to transition to lower carbon intensive fuels for our kilns, such as biogas, hydrogen or electricity. Technologies utilising these fuels are under development or not currently commercially available and, in the meantime, we will focus on improving the efficiency of the firing process.

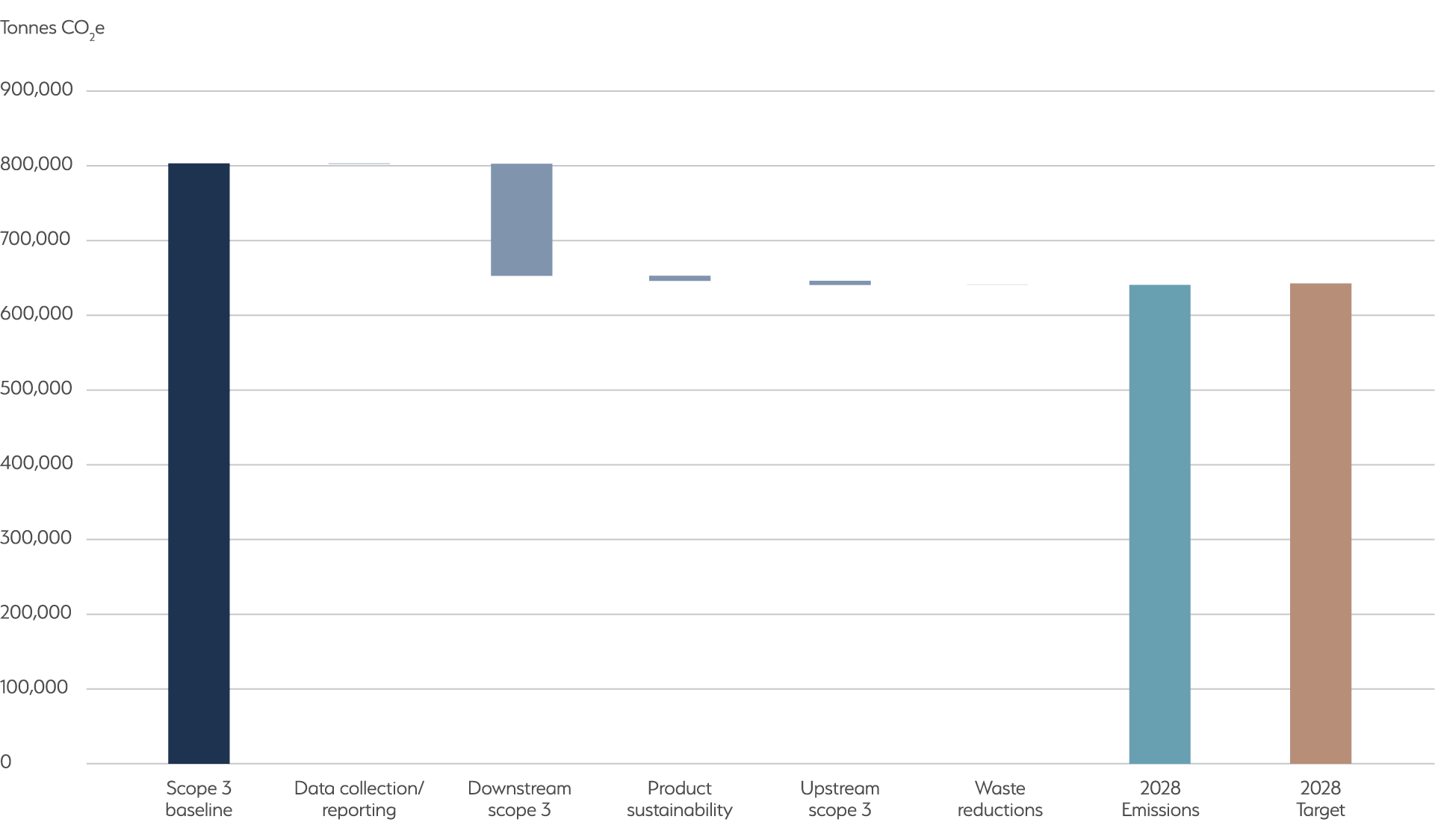

Our near-term targets for Scope 3 emissions are also not predicated on any major shift in strategy. We anticipate taking steps to move our product portfolio towards the incorporation of lower embedded carbon materials and to improved operating efficiency in use. This year, we have started to develop a Sustainable Products Framework that enables us to classify our products against their sustainability attributes. This methodology will allow us to monitor and shift our revenue exposure to sustainable products over time.

Whilst we will need to increase and improve our supply chain engagement, we already engage with many of our suppliers to determine the embodied carbon for certain raw materials and work together to “design out” carbon products and processes. We will continue to roll out this approach to an increased number of suppliers.

We are committed to identifying and actioning every available opportunity to achieve our targets. We created a high-level net zero plan that would take us to our near-term and long-term net zero 2040 target based on our full value chain carbon footprint for 2023. Our top-down Group targets were then translated into targets for each of our brands, incorporating the particular emissions exposures and drivers of the brands. Our brands have responded by assessing and collating bottom-up initiatives for Scopes 1, 2 and 3 emissions reduction. These initiatives are recorded centrally and provide a register of planned milestones by brand, which are tracked quarterly at the ESG Forum.

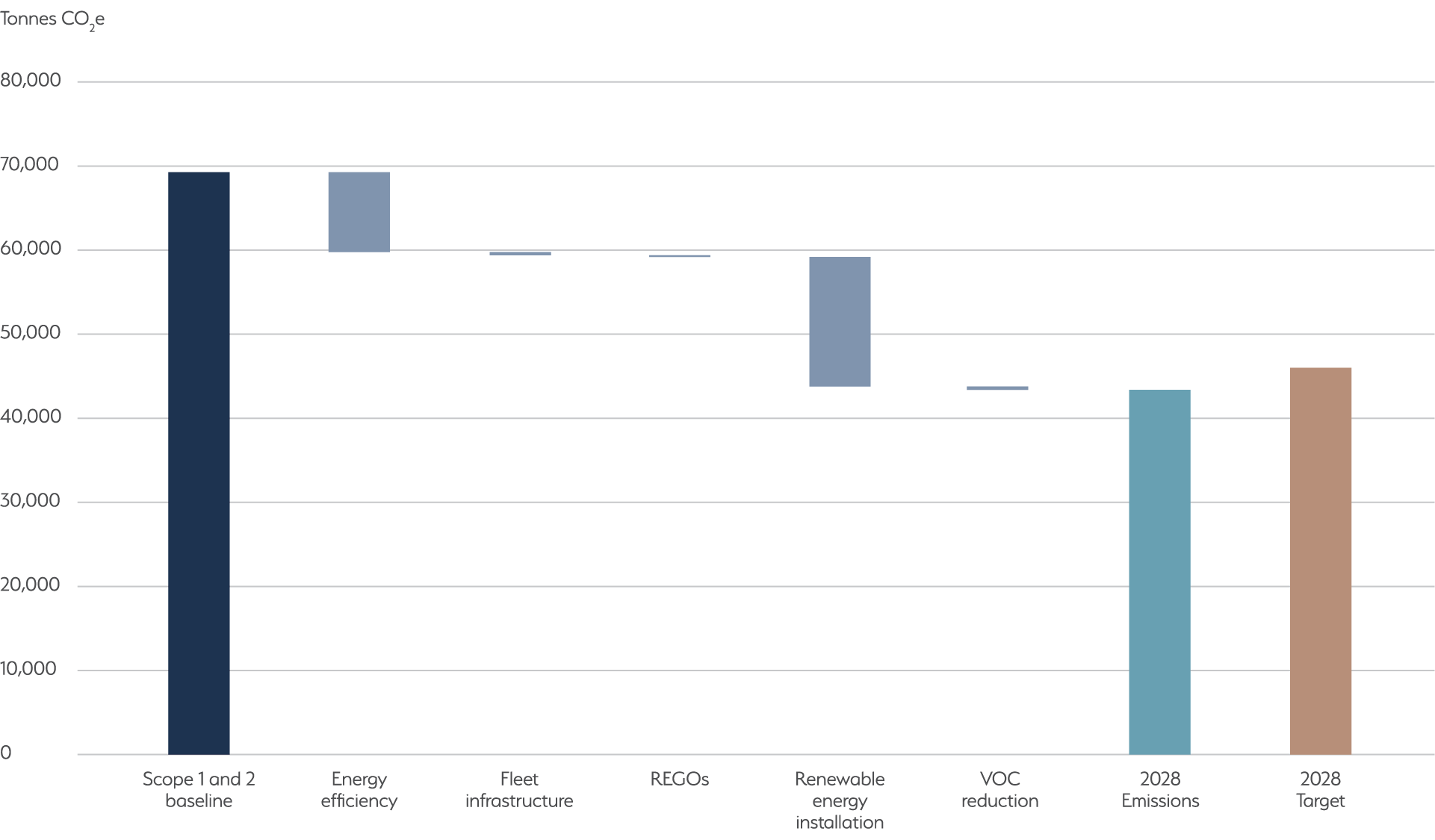

Our plan – Scope 1 and 2 emissions

Scope 1

The majority of our Scope 1 emissions relate to natural gas used in the kilns of our tile manufacturing businesses in both UK and South Africa. In the near term we are focusing on operational improvements such as heat recovery systems and retrofitting energy efficient burners to kilns. In the UK, we have also recently consolidated to one kiln to fire our tiles, which results in less energy used in the production process. At the start of the financial year ending March 2025, we announced the sale of Johnson Tiles UK, which will lead to a significant reduction in the Group’s Scope 1 emissions in 2025 as Johnson Tiles UK currently accounts for around 24% of our Scope 1 emissions.

Additionally, we are planning to decarbonise our vehicle fleet by replacing traditional internal combustion engine vehicles with electric or hybrid vehicles. Several of our brands have already increased the number of electric vehicles in their fleet and installed electric vehicle chargers on their sites. Triton, Merlyn and Grant Westfield have each set targets to make their entire fleets electric.

In the longer term, we will monitor technology development around kiln technologies such as electric, biogas or hydrogen kilns for our Johnson Tiles South Africa manufacturing facility. The Group will continue to support and contribute towards similar initiatives to provide us with options on transiting our kilns away from natural gas in the longer term.

Scope 2

The most significant reduction in our Scope 2 emissions will come from switching to renewable electricity supply, either through on-site renewables (e.g. rooftop solar installation at our main South African production site, and possibly Tile Africa and House of Plumbing sites) or securing purchased renewable electricity supply. The renewable energy market in South Africa is less mature than the UK market and therefore there is less availability, so we expect the transition to be slower for our South African brands.

We also expect grid decarbonisation to play a significant role in meeting our Scope 2 targets, especially in the long term – although, again, we expect the UK grid to decarbonise faster than the South African grid. We will also investigate the use of Energy Attribution Certificates (e.g. RECs and REGOs) to reduce our market-based Scope 2 emissions, although these are not central to us reaching our near term targets.

Scope 1 and 2 planned reductions

Our plan – Scope 3

Purchased goods and services account for 21% of our total emissions footprint and represent the embedded carbon within the raw materials and purchased items we procure. In the near term, we are looking to design products that are more easily recyclable and have lower embedded carbon, whilst also engaging with our suppliers to provide materials with a lower carbon impact.

Given our products’ use-phase emissions exposure, the single biggest factor in our ability to hit our near-term Scope 3 target and net zero by 2040 target is the pace of decarbonisation of grids globally, especially in the UK, which is our main market. We cannot directly influence the pace of grid decarbonisation and rely on governments to implement appropriate policies to achieve this. That said, we are encouraged by the forecasts in the UK’s Future Energy Scenarios, which see effective decarbonisation of the UK electricity grid by 2035 in three of the four modelled outcomes.

Our other main focus of Scope 3 emissions reduction is product innovation and supplier collaboration. Through product innovation, and in collaboration with our suppliers, we can influence emissions not only in their use-phase, but also in embedded emissions in our purchased goods and end of life. By investigating alternative materials, such as recycled material or raw materials that have acceptable technical qualities with lower carbon emissions, reducing the weight or number of components in our products and increasing the overall use-phase efficiency of our products, we can reduce both the upstream and downstream impacts of our product range, including the associated packaging. We are also looking into use-phase optimisation of certain products, such as Triton’s electric showers, by designing and manufacturing showering products to reduce the carbon footprint during use.

Most of our products are shipped by sea or by road. We are reviewing how we package and ship our products to look for opportunities for reducing the overall emissions footprint associated with logistics. We have factored in conservative assumptions on the decarbonisation of global transportation, which will drive the decarbonisation of logistics, business travel and employee commuting.

Scope 3 planned reductions