NORCROS IS STARTING TO MEAN SOMETHING MORE TO OUR COLLEAGUES, CUSTOMERS, STAKEHOLDERS AND INVESTORS. OUR BRAND REPUTATION FOR SUSTAINABILITY AND DESIGN IS GROWING.

One of our strategic objectives is to be renowned for sustainability. This means we are committed to managing our impact on the environment and designing sustainable products that minimise the use of water and energy. It is also about sustainability in the widest sense, including our people, governance and communities.

Read more in our standalone Sustainability Report 2025

Our ESG program is focused around three pillars:

We recognise the importance of doing the right thing for people – our employees, customers and key stakeholders.

Investing in our people and culture By fostering a supportive, empowering culture, we invest in our people, enabling each person to grow, thrive, and "Be Someone" who makes a difference. We are committed to investing in our workforce and developing our culture. We are continuously working towards a sustainable, safe and diverse working environment to help move the Group forward. We engage our customers, suppliers and other stakeholders who we see as partners in delivering our purpose.

Focus on design and sustainability

We design and develop innovative and sustainable products that enhance our customers’ lives and allow them to make sustainable choices.

We work closely with our key stakeholders and invest in research and development to ensure our products perform to the highest standards whilst helping our customers to achieve their sustainability goals.

Reducing environmental impact and engaging communities.

Reducing water and energy usage in our products and operations helps us nurture the world we love and share.

We are committed to minimising the environmental impact of our operations, products and services wherever possible. We work with local stakeholders to support the communities in which we live and work.

Achievements and priorities

Approval of

science-based targets

Our emissions targets have been approved by the Science Based Targets initiative (SBTi). This covers our long-term target of net zero emissions across our value chain by 2040 and near-term targets for Scopes 1, 2 and 3 for 2028 (from a 2023 base year).

Published the Group’s first Net Zero

Transition Plan

We have formalised the Group’s SBTi targets and action plans into a Transition Plan Taskforce (TPT) aligned Net Zero Transition Plan.

We continue to invest in carbon reduction initiatives as part of delivering our Net Zero Transition Plan

Recent examples include increasing the percentage of company fleet that is either electric or hybrid, installing LED lighting and energy efficient air conditioning units.

Submitted to CDP for the first time

We achieved a B grade in CDP Climate Change.

Created our Sustainable Products Framework

We use eight criteria, covering both the manufacturing and use phases, to assess our products under the Sustainable Products Framework. Each product is assigned a category based on how many criteria it meets, and whether those claims are verified to a third-party standard. Read more in our Sustainability Report

Enhancing supply chain management

Our Group Supply Chain Policy sets out our expectations in areas including labour rights, health and safety, climate change, anti-bribery and corruption, and water stewardship. It works in tandem with our Code of Ethics and Standards of Business Conduct, and together these frameworks support not just compliance, but also ongoing sustainable progress.

We continue to innovate in the development of low carbon products

Our brands and products play an increasingly meaningful role developing products that reduce and recycle. Triton’s water and energy saving ENVi® Shower won the Housebuilder "Best Kitchen and Bathroom Product" award 2024, and Grant Westfield won the Ideal Home "Best Bathroom Surface" award two years in a row with sustainable Multipanel’s Tile Collection in 2024 and Naturepanel in 2025. These are just a small selection of our awards across the Group.

Launch of Triton’s next generation electric shower, ENVi®

ENVi® became a ClimatePartner certified product through performing a full carbon life cycle analysis and was awarded a special commendation at the BMA Sustainability Awards. The ENVi® shower is expected to generate up to 70% less carbon emissions than a mixer shower connected to an A-rated combi boiler. We plan to drive sales of this product in all channels in financial year 2025.

Embedded our ESG Forum

This team meets regularly throughout the year to develop and review our ESG program. They have worked together to develop our Net Zero Transition Plan and we review progress against milestones each quarter.

BUILDING OUR CULTURE

#BeSomeone

The Norcros UK & Ireland Purpose & Keys Roadshow took place during spring 2025. We shared our exciting vision for the future, built connections, listened to feedback and celebrated the incredible people and teams who drive our success.

Case Studies

Norcros South Africa’s Women’s Forum

The Norcros South Africa Women’s Forum was established in recognition of the fact that the Group operates in an industry that has been historically male dominated, and therefore the structures and facilities in place have generally been designed to accommodate men. The Forum sets out to assist in improving and raising awareness for women within the manufacturing and retail space, working with businesses to improve working structures and facilities and eliminate identified barriers that hinder the desired representation of women within the space.

These barriers include:

- wage gap;

- career advancement limitations;

- home and work commitments;

- hostile work environments; and

- facilities and tools.

The Forum was created to identify and systematically eliminate these barriers, increasing diversity within the business and promoting equity and inclusion.

The Forum focuses on:

- building a community for internal networking;

- opportunities for females within the business;

- empowering women to become advocates for

themselves and other women in the business; - advising on the recruitment and retention of females in

the business; - advocating for the interests and concerns affecting

women; and - promoting professional development.

The Forum includes representatives from women across four South African brands, and includes women from diverse backgrounds, age, occupational levels and race.

The establishment of the Norcros South Africa Women’s Forum is a pivotal step in fostering a more diverse and inclusive working environment. Norcros South Africa remains committed to creating safe workspaces that openly support the development of women into the leadership structures and other areas of the business.

Supporting responsible forestry

Naturepanel is FSC®-certified. This ensures that the timber used originates from responsibly managed forests for complete customer assurance on responsible sourcing.

Our panels are 100% recyclable and we recycle 99% of post-production waste into biomass materials. We have also achieved ISO 14001, demonstrating our commitment to the environment.

Our Environmental Product Declaration (EPD) demonstrates that Naturepanel is one of the most sustainable wall coverings available in the UK.

Triton’s ENVi® shower

This year Triton launched their most ambitious product to date – the ENVi® electric shower.

Designed with style and sustainability in mind, ENVi® features a number of key functions that bring sustainable showering to users far more easily.

An integrated usage calculator tracks how much water and energy each shower uses, and estimates a cost per shower based on this information. Allowing people to see their usage helps them make informed decisions about the amount of time they spend in the shower, helping each of us to reduce our impact, both in our wallets, and on the planet.

What’s more, ENVi® features a built-in timer and Eco‑Mode, reducing shower time by one minute to encourage users to speed up and get clean, saving water and energy in the process.

Finally, ENVi® is Climate Partner Certified, meaning Triton, with Climate Partner’s support, calculated the full life cycle of the product, from cradle to grave, and have set and implemented reduction measures.

70%

UP TO 70% LOWER CO2 EMISSIONS1 THAN A MIXER SHOWER CONNECTED TO AN A-RATED COMBI BOILER

1 Calculated based on 3-person household, 5 showers pppw, 7.5 min average duration at 41°C

Putting policy into practice: the way our brands are engaging with suppliers

Whilst Group-wide mechanisms continue to evolve, many of our brands are already taking proactive steps to raise standards and increase visibility in their supply chains. The examples below illustrate a selection of the ways different parts of the Group are putting our Supply Chain Policy into action:

- Triton requires all key suppliers – epresenting around 80% of spend – to undergo external social audits, typically via the SMETA framework, and in-person site visits twice a year by Triton staff. Suppliers are also expected to have, or be working towards, ISO 14001 certification.

- VADO conducts bi-annual supplier reviews using the amfori BSCI audit framework as a key reference point, with a minimum expected score of “B”. In 2025, VADO also introduced sustainability metrics – including carbon targets – into supplier performance evaluations, offering support for suppliers looking to set or meet science‑based goals.

- Grant Westfield carried out supplier visits in regions including China, India and Europe, with a particular focus on identifying any risk of forced or child labour. The business has also joined Timber Development UK, reinforcing its commitment to responsible sourcing and helping to drive industry-wide change. All of Grant Westfield’s timber products are FSC certified.

These activities demonstrate our belief that sustainability and human rights must be actively managed, not assumed. Supplier relationships are built on clear expectations, open dialogue and a shared ambition to improve – for people and for the planet.

Triton’s supplier engagement

Triton recognises the role it needs to play in collaborating with its supply chain partners to influence the full up-and-downstream carbon impact, and are working to give them focus and support so they can join its carbon reduction journey. In the last two years, Triton have carried out detailed supplier audits covering all areas of quality, health and safety, and environmental systems and practises, as well as desktop audits covering energy and water usage.

In 2023, Triton partnered with Contingent, an expert in the field of sustainable supply chains. With Contingent’s support, Triton launched its Sustainability Operating System (SOS) to key suppliers. This engagement provides expert knowledge and an operating model that tracks actions and benefits, and provides Triton with a single view on all supply chain sustainability activity.

By working together this way, Triton are helping its partners take key steps towards their own carbon reduction journeys, whilst they help Triton on its net zero journey.

Energy efficiency initiatives

We continue to implement energy efficiency initiatives across the Group to reduce our carbon footprint. Highlights from this year include:

- Croydex replaced all office windows with new double glazing to improve thermal efficiency and reduce heating demand. New air conditioning units are being phased in, expected to further increase energy efficiency.

- MERLYN retrofitted LED lighting in its head office and warehouse. EV chargers were also installed at the office and in the homes of employees driving EVs.

- Triton connected its building control system to the warehouse and production gas heaters, which is anticipated to reduce gas heating consumption by 25%. Two electric forklifts were replaced, with expected energy savings of 400kWh, and 55% of their vehicle fleet is now electric.

- Norcros South Africa continued its programme to replace older air conditioning units with more energy-efficient models using lower-impact refrigerants. 30 Tile Africa branches now operate inverter air conditioning units.

TRITON AWARDED FOR SUSTAINABILITY

At Triton, a deep commitment to sustainability is central to its long-term business strategy – and this has helped it achieve the prestigious King’s Award for Enterprise in Sustainable Development. The awards were set up to celebrate the success of innovative, pioneering UK organisations, and Triton is one of only 29 to be recognised for its contribution to sustainable development. Part of Norcros plc since 1987, Triton is a market leader in electric showers. In 2019, the business set ambitious targets for reducing its carbon footprint and impact on the environment, across all aspects of its operations and product development. Electric showers produce up to 70% lower CO2 emissions1 than a mixer shower connected to an A-rated combi boiler. They also use less water, and Triton works hard to make the most of these efficiencies through continuous investment in research and development. An example is Triton’s ENVi® electric shower, which features a usage calculator that tracks how much water and energy each shower uses and estimates the cost per shower based on this information. Seeing their usage helps people make informed decisions about the amount of time they spend in the shower, and so save money as well as reduce emissions.

Innovations such as ENVi® are typical of Triton’s approach to sustainability. As market leader, it focuses its resources and expertise on ways of saving water and energy that benefit its customers, their consumers and the environment.

70%

ELECTRIC SHOWERS PRODUCE UP TO 70% LOWER CO2 EMISSIONS1 THAN A MIXER SHOWER CONNECTED TO AN A-RATED COMBI BOILER

29

TRITON IS ONE OF ONLY 29 UK ORGANISATIONS TO BE RECOGNISED FOR A KING’S AWARD FOR ENTERPRISE IN THE SUSTAINABLE DEVELOPMENT CATEGORY

1Calculated based on a three-person household, five showers per person per week, 7.5-minute average duration at 41°C.

OUR EMISSIONS TARGETS AND NET ZERO PLAN

Recognising the urgent need to address climate change and reduce greenhouse gas emissions, we have developed ambitious net zero targets and a high-level decarbonisation pathway to manage our value chain emissions going forward. This aligns with our strategy of using ESG to drive our competitive advantage.

As the UK and Ireland’s number one bathroom products group and a leading supplier of bathroom and kitchen products in our geographical markets, our business model already integrates certain emissions-reduction activities and products with sustainable attributes, and we will be increasing our focus on these areas to align our business and our products with a net zero world.

Download further information here

OUR EMISSIONS TARGETS

AND NET ZERO PLAN

Recognising the urgent need to address climate change and reduce greenhouse gas emissions,

we have developed ambitious net zero targets and a high-level decarbonisation pathway to manage our value chain emissions

going forward. This aligns with our strategy of using ESG to drive our competitive advantage.

Targets

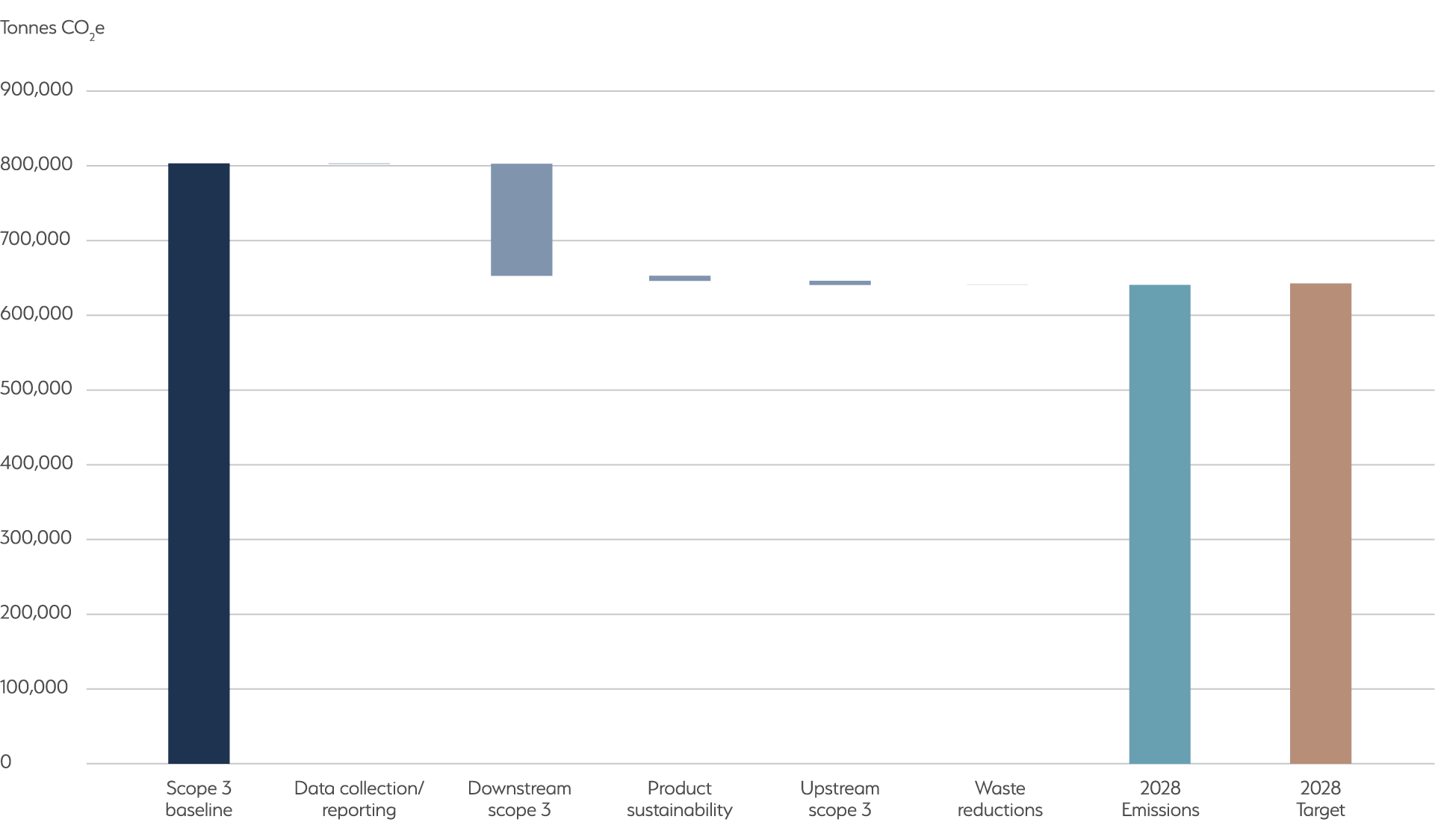

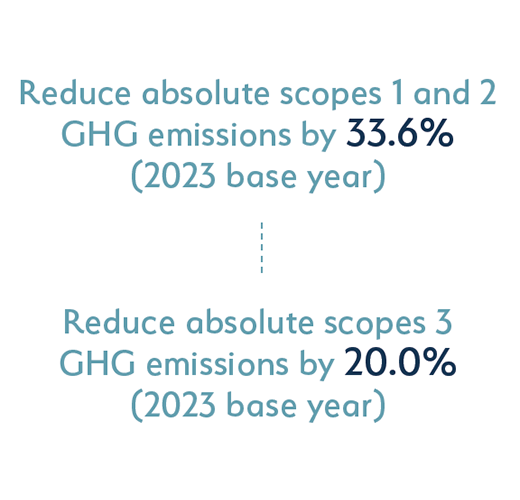

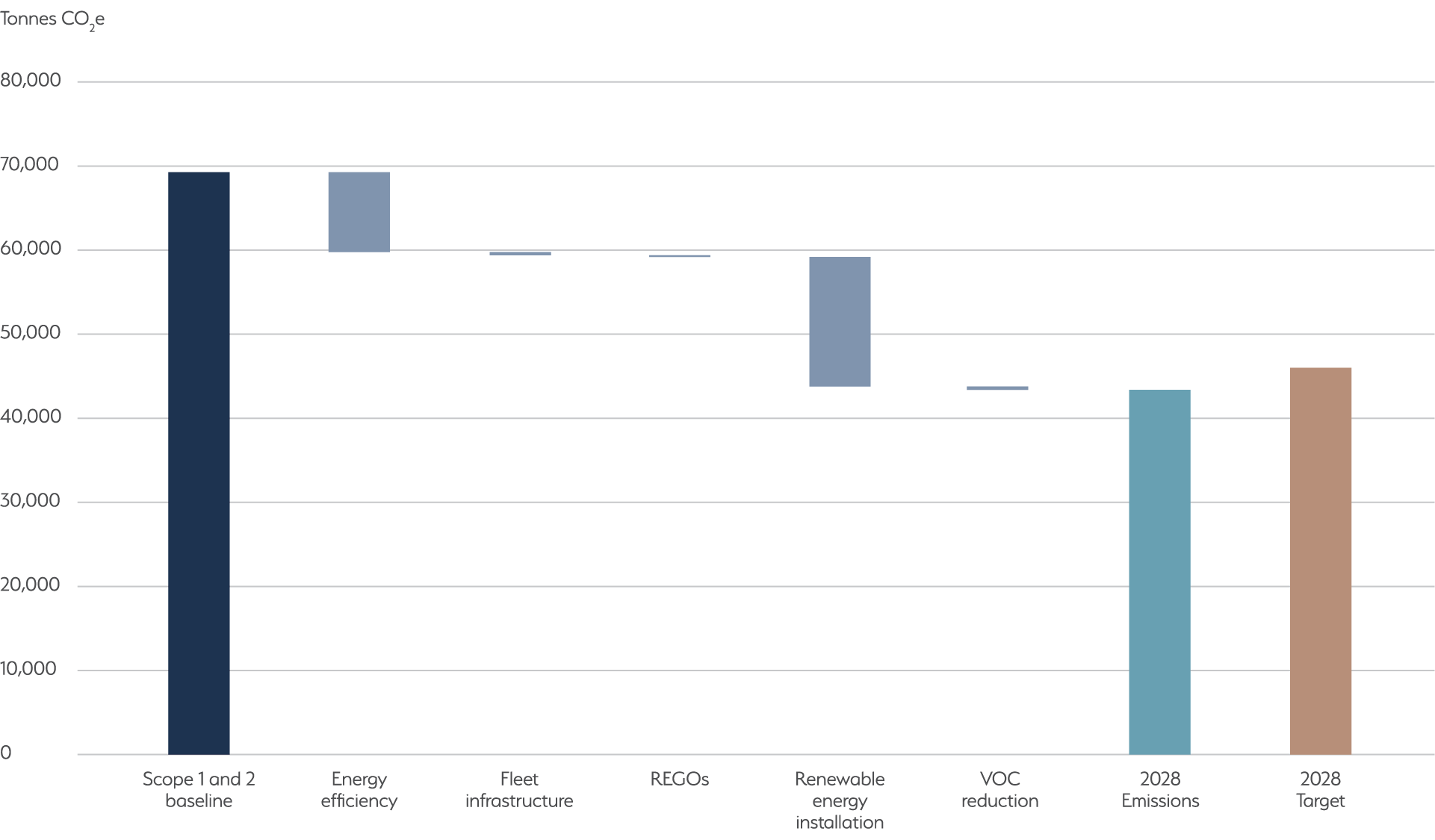

We have set science-based targets across Scopes 1, 2 and 3, which affirm our long-term commitment to net zero by 2040, and we have introduced interim targets for 2028. Our targets were validated by the Science Based Targets initiative (SBTi) in January 2024 and they provide a path for significant reduction in our emissions by 2028 and beyond.

By 2028, we have set the following targets:

- Reduce absolute Scopes 1 and 2 GHG emissions by 33.6% (2023 base year)

- Reduce absolute Scope 3 GHG emissions by 20.0% (2023 base year)

By 2040, our target is to reach net zero GHG emissions across the value chain.

Business model implications

As the UK and Ireland’s number one bathroom products group and a leading supplier of bathroom and kitchen products in our geographical markets, our business model already integrates certain emissions-reduction activities and products with sustainable attributes, and we will be increasing our focus on these areas to align our business and our products with a net zero world.

In developing our near-term decarbonisation plan for Scope 1 and 2, we assumed no material changes in our business model, locations or asset footprint or value chain impacts. Our belief is that we can make the necessary emissions reduction to our operations within a business-as-usual environment, utilising typical replacement cycles or initiatives that do not incur material capital expenditure or operational disruption. Beyond our near-term target date of 2028, we are reliant on the development of new technologies to reduce operational emissions to zero, in particular in the production of ceramic tiles (where we manufacture tiles in South Africa). In order to meet our emissions reduction targets, we will need to transition to lower carbon intensive fuels for our kilns, such as biogas, hydrogen or electricity. Technologies utilising these fuels are under development or not currently commercially available and, in the meantime, we will focus on improving the efficiency of the firing process.

Our near-term targets for Scope 3 emissions are also not predicated on any major shift in strategy. We anticipate taking steps to move our product portfolio towards the incorporation of lower embedded carbon materials and to improved operating efficiency in use. This year, we have started to develop a Sustainable Products Framework that enables us to classify our products against their sustainability attributes. This methodology will allow us to monitor and shift our revenue exposure to sustainable products over time.

Whilst we will need to increase and improve our supply chain engagement, we already engage with many of our suppliers to determine the embodied carbon for certain raw materials and work together to “design out” carbon products and processes. We will continue to roll out this approach to an increased number of suppliers.

We are committed to identifying and actioning every available opportunity to achieve our targets. We created a high-level net zero plan that would take us to our near-term and long-term net zero 2040 target based on our full value chain carbon footprint for 2023. Our top-down Group targets were then translated into targets for each of our brands, incorporating the particular emissions exposures and drivers of the brands. Our brands have responded by assessing and collating bottom-up initiatives for Scopes 1, 2 and 3 emissions reduction. These initiatives are recorded centrally and provide a register of planned milestones by brand, which are tracked quarterly at the ESG Forum.

Our plan – Scope 1 and 2 emissions

Scope 1

The majority of our Scope 1 emissions relate to natural gas used in the kilns of our tile manufacturing businesses in both UK and South Africa. In the near term we are focusing on operational improvements such as heat recovery systems and retrofitting energy efficient burners to kilns. In the UK, we have also recently consolidated to one kiln to fire our tiles, which results in less energy used in the production process. At the start of the financial year ending March 2025, we announced the sale of Johnson Tiles UK, which will lead to a significant reduction in the Group’s Scope 1 emissions in 2025 as Johnson Tiles UK currently accounts for around 24% of our Scope 1 emissions.

Additionally, we are planning to decarbonise our vehicle fleet by replacing traditional internal combustion engine vehicles with electric or hybrid vehicles. Several of our brands have already increased the number of electric vehicles in their fleet and installed electric vehicle chargers on their sites. Triton, Merlyn and Grant Westfield have each set targets to make their entire fleets electric.

In the longer term, we will monitor technology development around kiln technologies such as electric, biogas or hydrogen kilns for our Johnson Tiles South Africa manufacturing facility. The Group will continue to support and contribute towards similar initiatives to provide us with options on transiting our kilns away from natural gas in the longer term.

Scope 2

The most significant reduction in our Scope 2 emissions will come from switching to renewable electricity supply, either through on-site renewables (e.g. rooftop solar installation at our main South African production site, and possibly Tile Africa and House of Plumbing sites) or securing purchased renewable electricity supply. The renewable energy market in South Africa is less mature than the UK market and therefore there is less availability, so we expect the transition to be slower for our South African brands.

We also expect grid decarbonisation to play a significant role in meeting our Scope 2 targets, especially in the long term – although, again, we expect the UK grid to decarbonise faster than the South African grid. We will also investigate the use of Energy Attribution Certificates (e.g. RECs and REGOs) to reduce our market-based Scope 2 emissions, although these are not central to us reaching our near term targets.

Scope 1 and 2 planned reductions

Our plan – Scope 3

Purchased goods and services account for 21% of our total emissions footprint and represent the embedded carbon within the raw materials and purchased items we procure. In the near term, we are looking to design products that are more easily recyclable and have lower embedded carbon, whilst also engaging with our suppliers to provide materials with a lower carbon impact.

Given our products’ use-phase emissions exposure, the single biggest factor in our ability to hit our near-term Scope 3 target and net zero by 2040 target is the pace of decarbonisation of grids globally, especially in the UK, which is our main market. We cannot directly influence the pace of grid decarbonisation and rely on governments to implement appropriate policies to achieve this. That said, we are encouraged by the forecasts in the UK’s Future Energy Scenarios, which see effective decarbonisation of the UK electricity grid by 2035 in three of the four modelled outcomes.

Our other main focus of Scope 3 emissions reduction is product innovation and supplier collaboration. Through product innovation, and in collaboration with our suppliers, we can influence emissions not only in their use-phase, but also in embedded emissions in our purchased goods and end of life. By investigating alternative materials, such as recycled material or raw materials that have acceptable technical qualities with lower carbon emissions, reducing the weight or number of components in our products and increasing the overall use-phase efficiency of our products, we can reduce both the upstream and downstream impacts of our product range, including the associated packaging. We are also looking into use-phase optimisation of certain products, such as Triton’s electric showers, by designing and manufacturing showering products to reduce the carbon footprint during use.

Most of our products are shipped by sea or by road. We are reviewing how we package and ship our products to look for opportunities for reducing the overall emissions footprint associated with logistics. We have factored in conservative assumptions on the decarbonisation of global transportation, which will drive the decarbonisation of logistics, business travel and employee commuting.

Scope 3 planned reductions